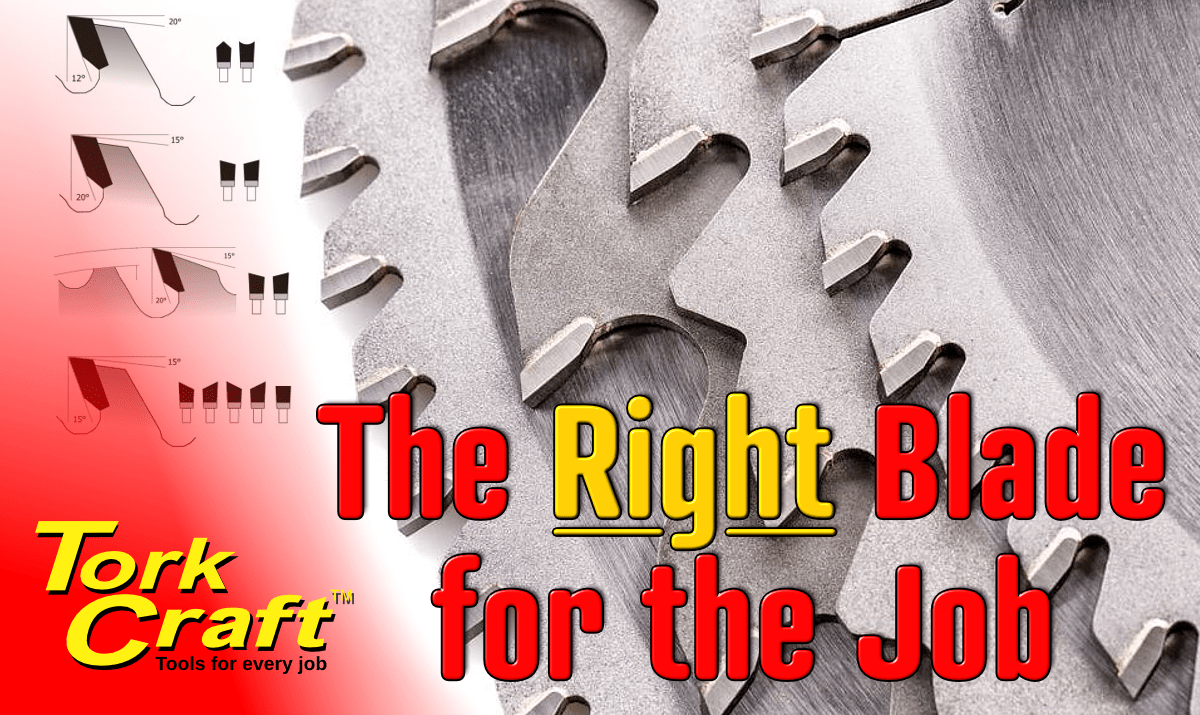

Choosing the right blade for the job

Saw Blade Types

With the wide variety of specialty saw blades available today, selecting the right one can significantly improve the quality of work. While the most common blades are designed for ripping and crosscutting solid wood, there are also specialty blades specifically made for cutting man-made materials like MDF and plywood, plastic-coated surfaces such as melamine, and even demolition blades designed to cut through nails and other tough materials.

Whether you're ripping thousands of oak boards, mitering fine moldings, or cutting hardwood veneered plywood, we have the perfect blade for the job. Choosing the right saw blade is critical to achieving success—no matter how high-quality your saw is, it won't perform well with the wrong or subpar blade. In fact, the blade is the most important part of any saw.

Today, there are more blade options than ever before. While this ensures you can find a blade for any task, it can also make choosing the right one a bit overwhelming. Let's break down the different types of blades and the key terminology, so you can confidently select the best blade for your next project.

Our saw blades are engineering marvels, but you don't need to be an expert to understand the basics. Here's a quick overview of essential terms:

-

Steel Plate (Blade Body): The blade's body is dynamically straightened, balanced, and tensioned through a three-step process. This ensures that each blade cuts cleanly and accurately. Standard saw blades have thicker plates, offering smoother cuts compared to thin-kerf blades, though thin-kerf blades generally require less horsepower.

-

Expansion Slots: As the blade heats up and expands during cutting, expansion slots help dissipate heat and allow for blade expansion, ensuring it stays flat and cuts true.

-

Noise Reduction: Copper plugs inserted into the expansion slots help to minimize operational noise.

-

Carbide Teeth: Each blade's carbide teeth are precisely ground for clean cuts. The best blades feature thick teeth, allowing for multiple sharpenings and extended blade life.

-

Gullets: Rip blades feature large gullets designed to efficiently clear sawdust from the kerf, ensuring smoother and faster cuts.

By understanding these key elements, you can easily choose the right saw blade for any job, ensuring top-notch performance and results.

Rip Saw Blades

Ripping hardwood can push a saw to its limits, but a quality rip blade reduces strain on both the operator and the saw. Rip blades are designed for efficient, smooth cuts while minimizing resistance. These blades typically have fewer teeth than crosscut or combination blades—usually 20 to 24 teeth on a 10-inch blade. The lower tooth count, combined with large gullets and an 18 to 20-degree hook angle, makes rip blades fast and aggressive.

Glue-line rip blades feature a special triple-chip tooth grind and a high hook angle, allowing for aggressive feed rates while producing cuts so smooth that no additional jointing is needed before gluing.

Melamine, Plywood & Laminate Saw Blades

Cutting plywood and plastic laminates without chipping can be challenging due to their thin veneer and brittle nature. Plywood and laminate saw blades eliminate chipping and splintering thanks to their high Alternate Top Bevel (ATB) grind. This design produces smooth finishes on various sheet materials, including hardwood-veneered plywood, MDF, and laminate, making these blades ideal for custom cabinetry work.

General Purpose Saw Blades

General purpose blades are versatile and designed to handle both ripping and crosscutting without frequent blade changes. These blades combine a lower tooth count and larger gullets, similar to rip blades, with an ATB configuration, making them effective for clean crosscuts as well.

For most tasks, a furniture maker might use a combination blade on a table saw, saving time by avoiding constant switching between rip and crosscut blades. However, for specific jobs like ripping large stacks of hardwood, switching to a dedicated rip blade is more efficient. For precise miter cuts, an 80-tooth miter blade with a 20-degree top bevel is often preferred for its clean, sharp results.

Crosscut Saw Blades (Radial Arm and Mitre Saw)

For sliding miter saws or radial-arm saws, crosscut blades designed specifically for these machines are essential. These saws tend to self-feed, which can tear the wood and even grab the stock, creating a potential safety hazard. Crosscut blades with a negative hook angle push the material downward and against the fence, enhancing safety and providing clean cuts.

Miter Saw Blades

Miter saw blades, such as those with 60 teeth and a 2-degree negative hook angle, are ideal for producing smooth, ready-to-assemble miters. These blades are well-suited for both miter saws and radial-arm saws, delivering glass-smooth cuts necessary for precise woodworking.

Non-Ferrous Saw Blades

Non-ferrous saw blades are designed specifically for cutting materials like brass, copper, and aluminum. These blades feature a negative hook angle, triple-chip grind, and a thicker plate for durability. The range includes blades engineered for both thick-walled and thin-walled non-ferrous materials.

Demolition Saw Blades

Demolition blades, with a negative 15-degree hook angle and carbide made from 90% tungsten and 10% cobalt, are built to withstand shock and resist brittleness. These blades are a popular choice among rescue workers. However, they are not suitable for use with gas-powered saws.

Selecting the right saw blade enhances efficiency and improves the quality of cuts. Specialty blades are designed to offer specific advantages for particular tasks, and switching to the appropriate blade for the job can significantly boost productivity.